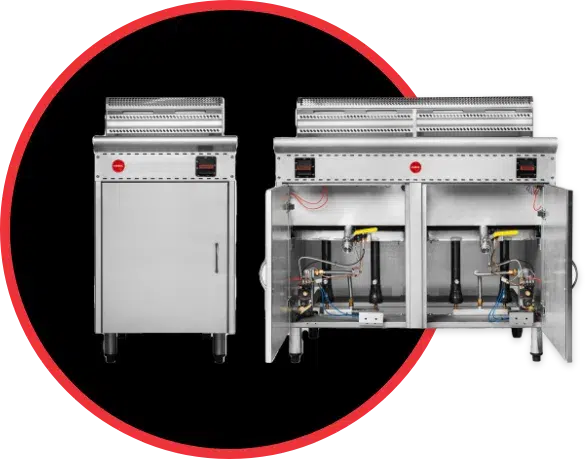

All stainless steel insulated external panels

304 stainless steel ripple base easy clean pan design

10yr gold star limited warranty on stainless pans

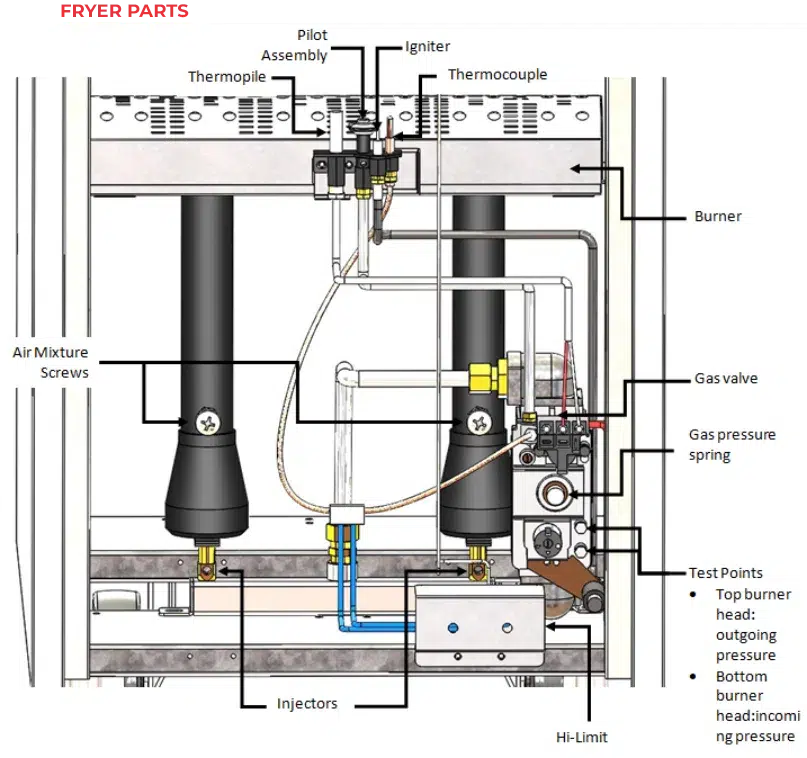

Cookon design burners

Gold contact thermostat controls

Overtemp safety cut out

Removable basket holder

3 baskets per pan

Fish plate

Night lid

Rear castors

Adjustable front legs

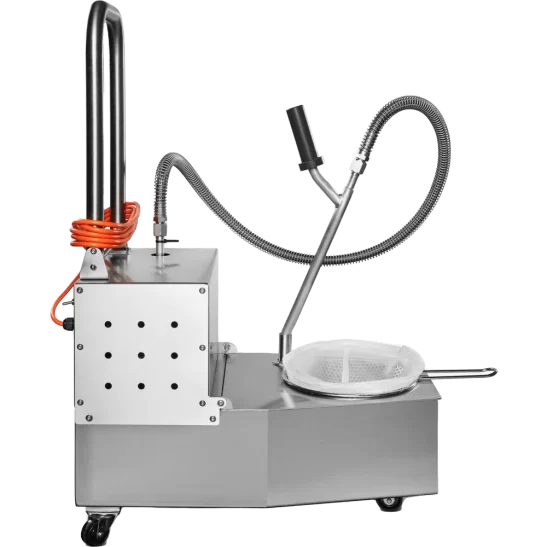

KBS-4S oil filter machine

Stainless steel joining strip

Extra Baskets

GAS TYPE

Natural or LPG

(Specify when ordering)

GAS CONNECTION

¾” (BSP) male

GAS RATINGS

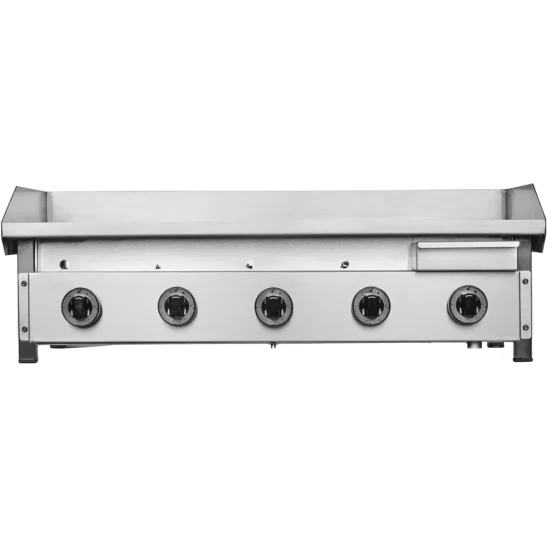

FFR-1-525S @ 74MJ/hr

FFR-2-525S @ 148MJ/hr

COOKING CAPACITY

FFR-1-525S @ 30kg/hr

FFR-2-525S @ 60kg/hr

*cooking capacity based on frozen product @ – 18°C cooked per hour

DIMENSIONS (MM)

FFR-1-525S: 531 x 753 x 1095

FFR-2-525S: 1062 x 753 x 1095

OIL CAPACITY

FFR-1-525S @ 40ltrs

FFR-2-525S @ 80ltrs

GLOBAL MARK APPROVAL NO

GA-102405-006

AUSTRALIA’S BUSIEST KITCHENS RELY ON COOKON

Fryer Arrival and Installation

Upon arrival, carefully inspect the appliance for concealed damage. Immediately report any damage to the manufacturer. Remove any plastic protection film from the stainless steel surface. Proper installation is essential for efficient and trouble free operation. Any alteration to the equipment voids the warranty.

Installation must be carried out only by an authorised person. Installation must be made in accordance with Australian Standard AS/NZS 5601 (Gas Installations),AS1668.2 (Extraction Canopy Installation Code) and all other Local Authority Codes.

The following procedure must be carried out on this appliance:

Remove all plastic film from the stainless steel panels along with any plastic film, glues, etc.

Ensure the surface on which the appliance is to be mounted on is of sufficient strength to support the appliance.

Ensure that the appliance is level when situated in its operating position and that the unit is secured accordingly to comply with required appliance installation codes.The appliance area must be kept clear of any combustibles.

AUSTRALIA’S BUSIEST KITCHENS RELY ON COOKON

Fryer Maintenance

- 2 x Manometers or digital pressure testing equipment to 10kPa.

- 1 x Digital multimeter.

- 1 x Digital temperature meter (accurate to 1 degree Celsius).

- 1 x 300°C immersion probe.

- 1 x 300°C oven probe.

- 1 x Number drill set and number drill sizing chart.

- Test points and bubble leak equipment.

- 1 x Electronic gas leak detector.

- Service tools, spanners, etc.

- Gas thread tape and sealant.

- Work method statements and work safe procedures.

- Safety gear (i.e. gloves, mats, etc.) are required if working on live electrical equipment.

- The service and technical manual.

AUSTRALIA’S BUSIEST KITCHENS RELY ON COOKON

CLEANING & MAINTENANCE

GENERAL

To ensure that the unit operates efficiently and has a long operational lifetime, it must beproperly maintained and cleaned regularly. The appliance must be kept clean during the working day and must be thoroughly cleaned at the end of each day.

STAINLESS STEEL

The only cleaning generally required on stainless steel surfaces is to wipe the surface with a cloth and mild dish-washing liquid as follows:

- Gently sponge the area to be cleaned, with a cloth and cleaning solution

- Wipe the surface dry with an absorbent dry cloth.

- Persistent stains may require vigorous rubbing with a sourer or with a creamed powder cleanser.

- Allow the appliance to cool down to ambient temperature by natural means.

PILOT BURNER ZIP TUBE

Brush with a wire brush daily after use or as often as required. Brushing will keep the holes in the burner open and reduce flame failure.

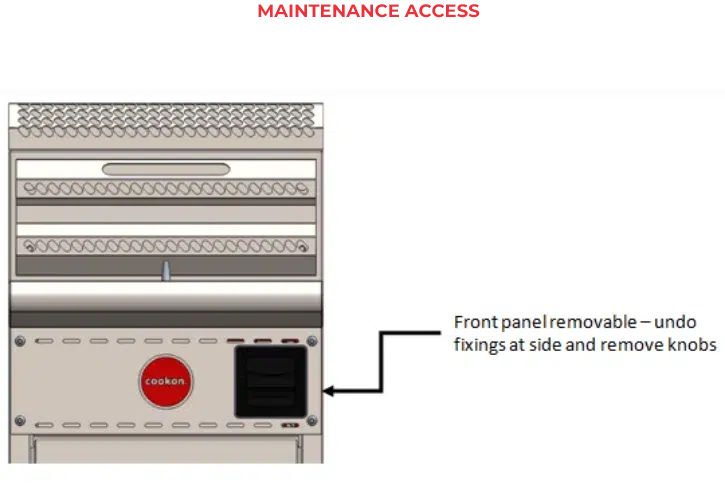

CONTROL PANEL

Wipe with a cloth dipped in warm cleaning solution as detailed above. The knobs of the burner controls can be removed by pulling them out.

WARNING

Aerosol sprays such as stove cleaners, insect sprays, etc. must NOT be used in the vicinity of this appliance whilst it is in operation, as they can cause corrosion of the metal surfaces.

Contact Us Today

For more information on our commercial kitchen equipment suppliers, contact us today or call us on (07) 3267 1133.

Reviews

There are no reviews yet.